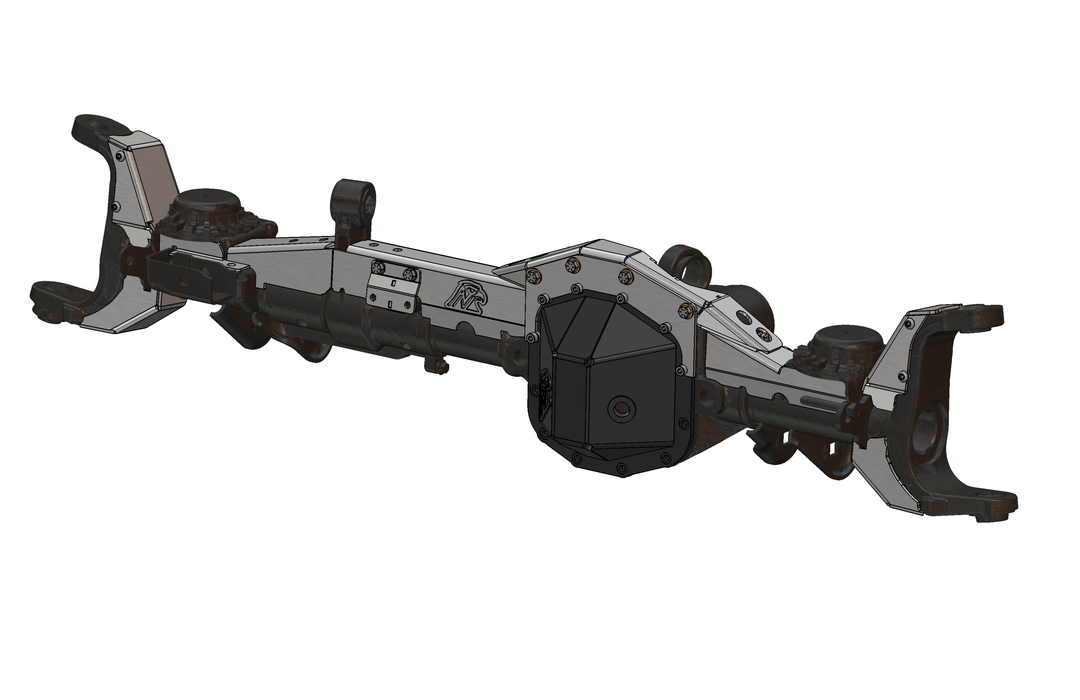

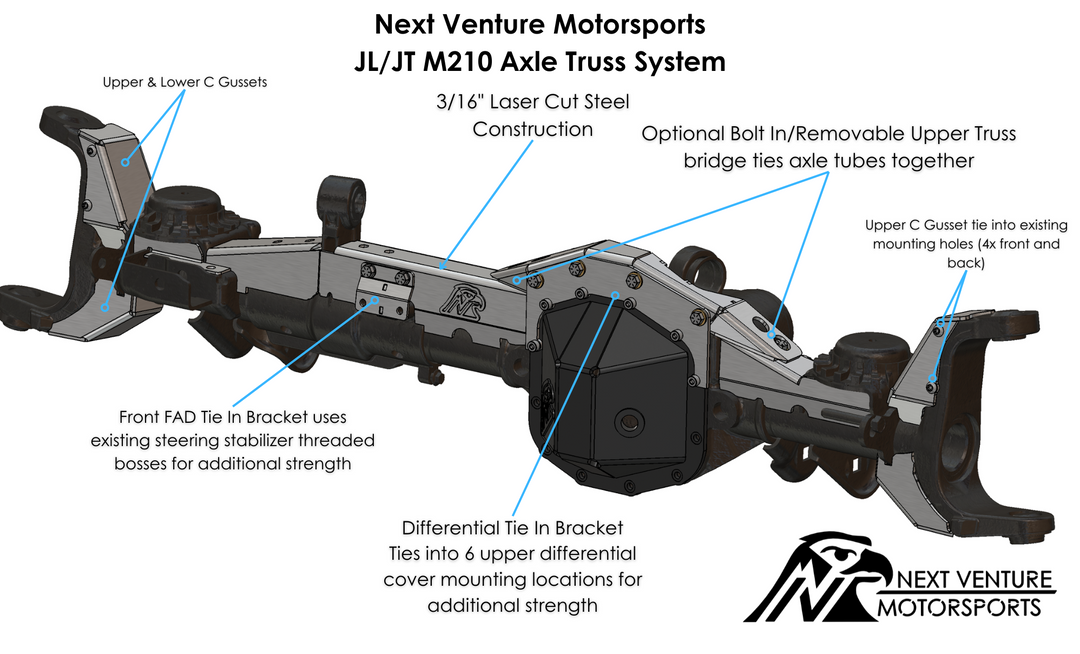

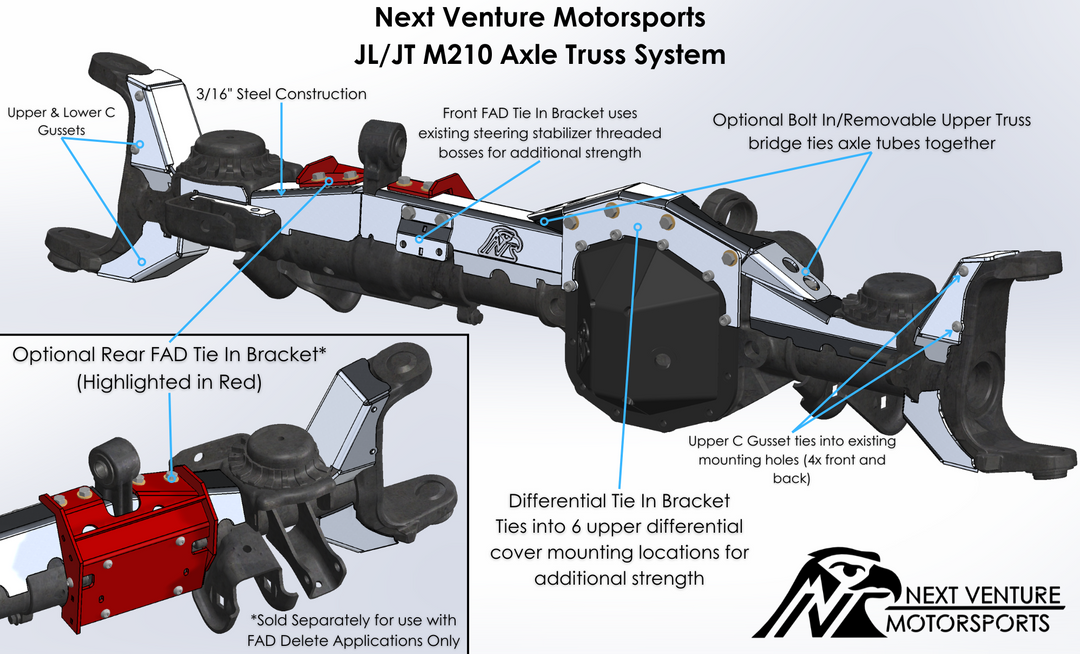

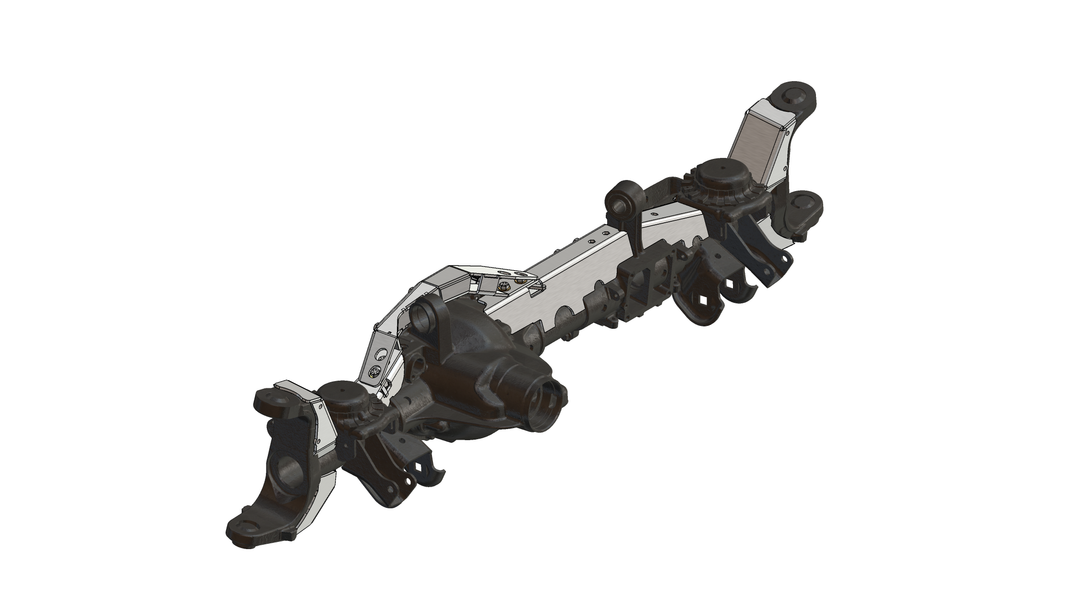

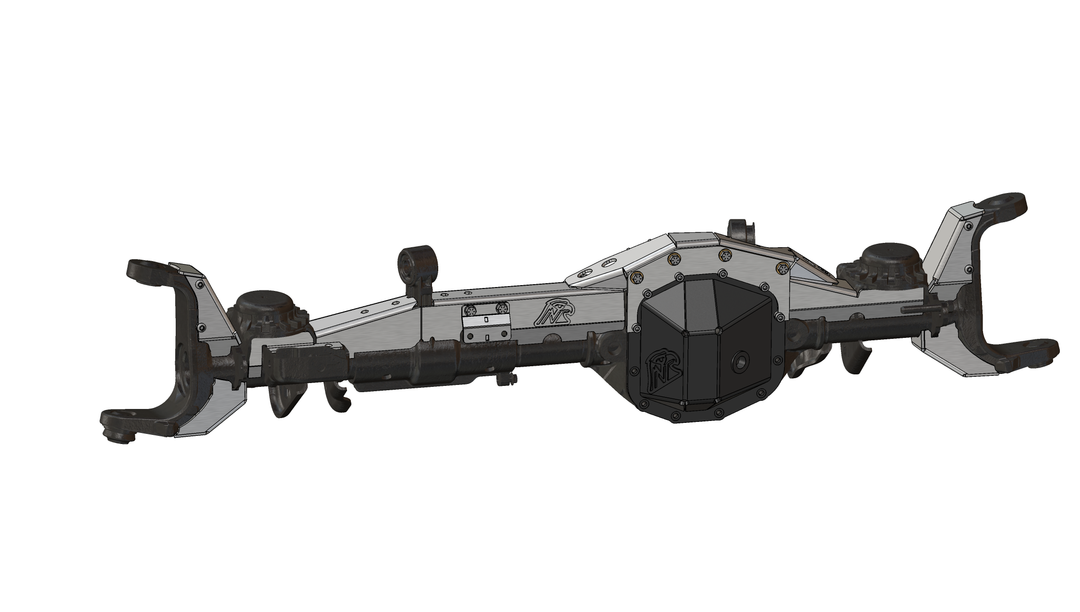

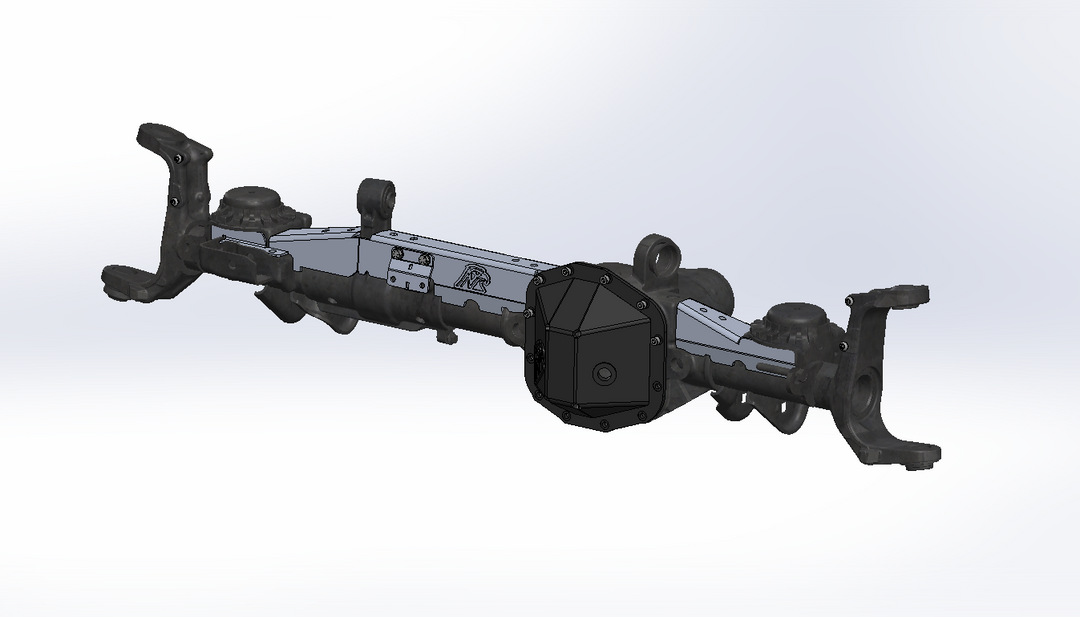

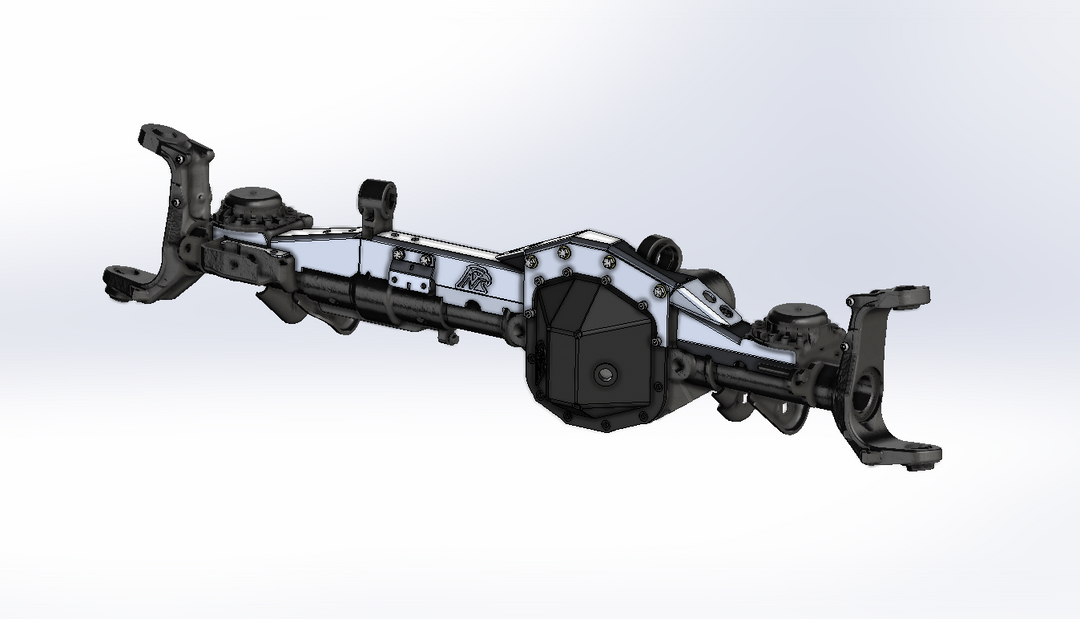

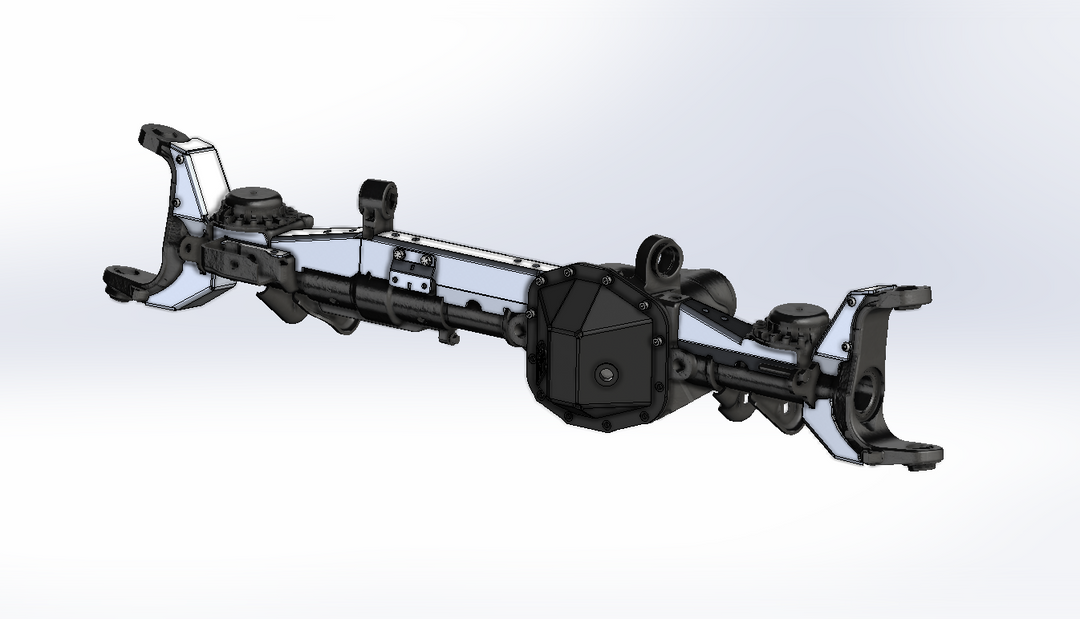

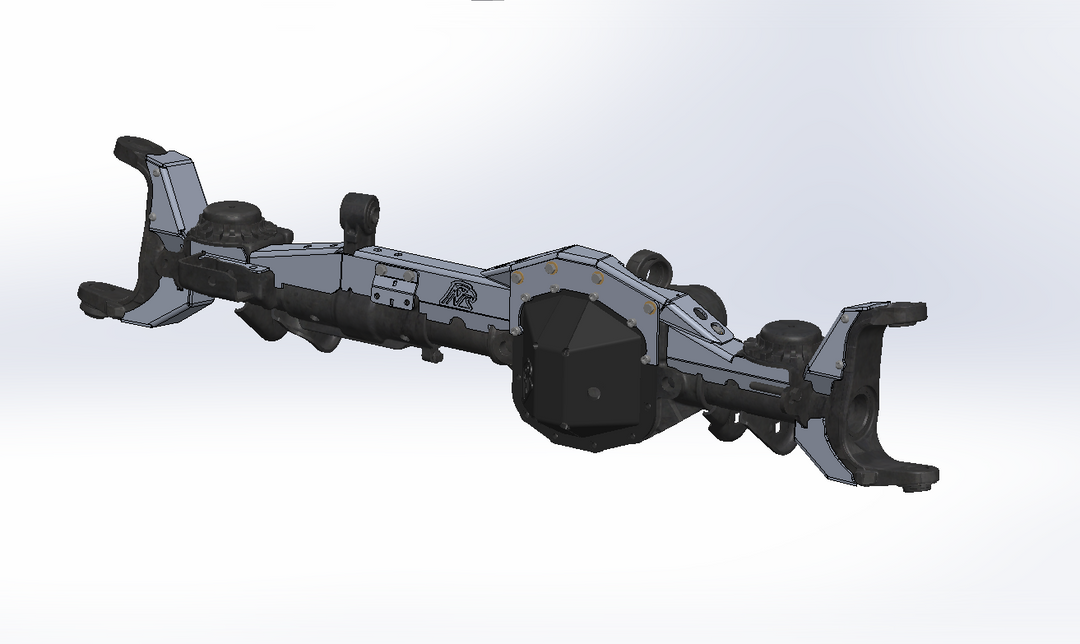

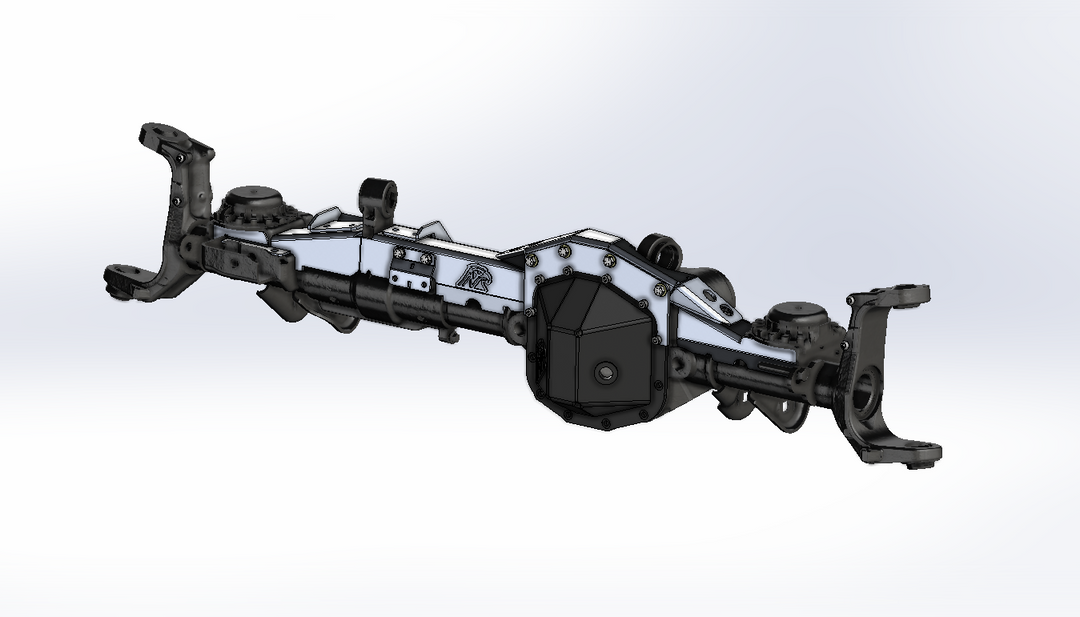

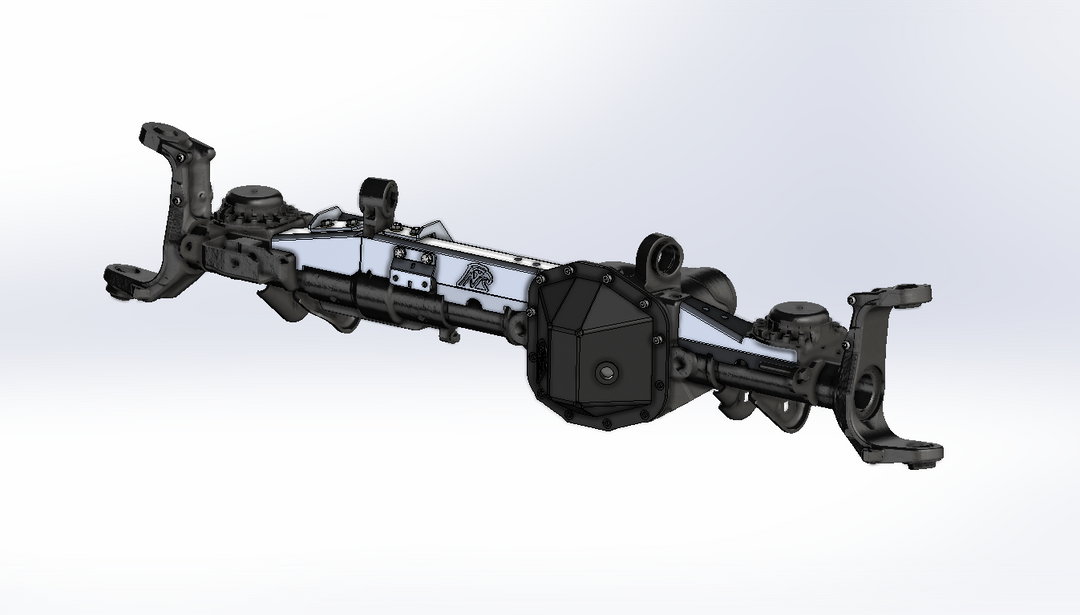

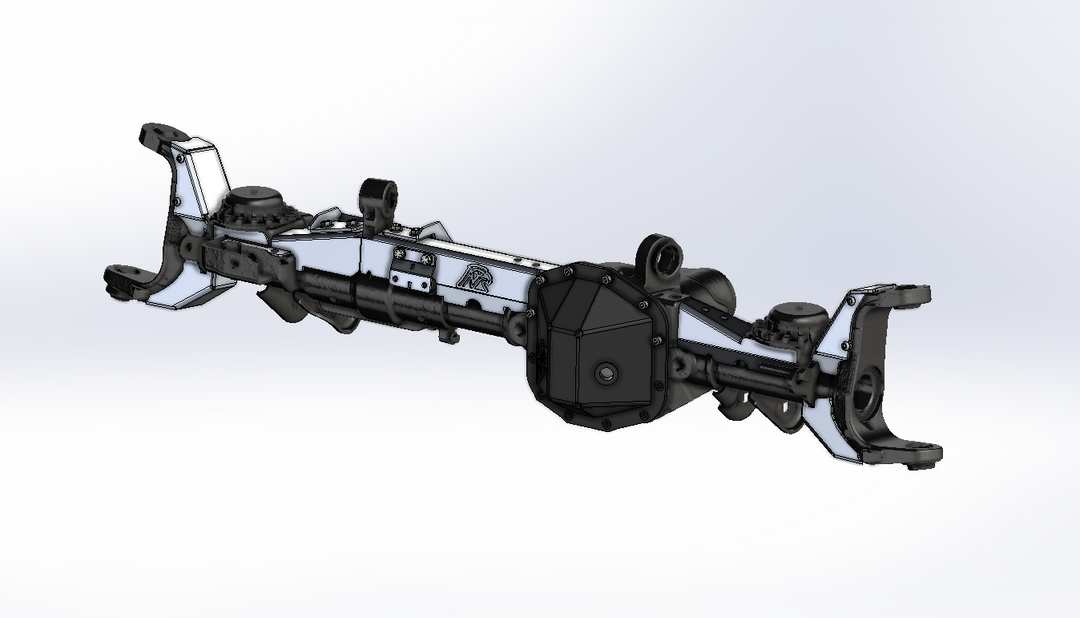

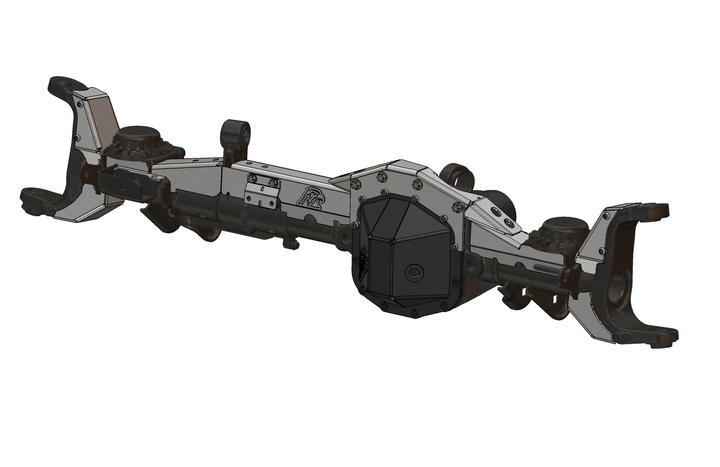

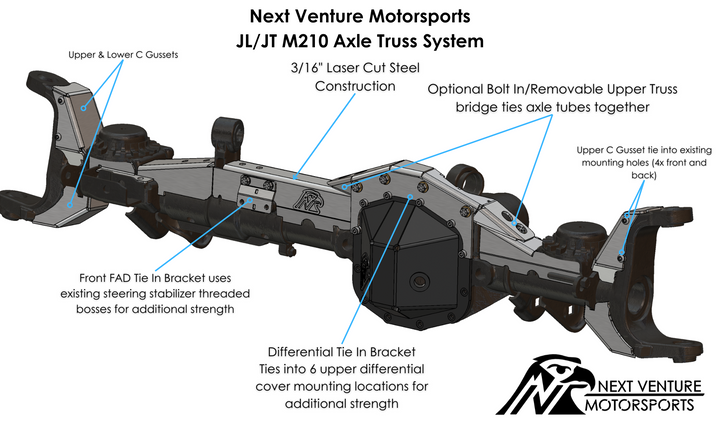

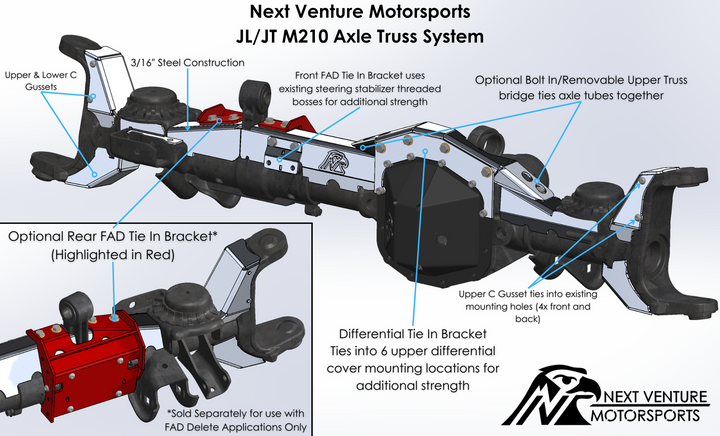

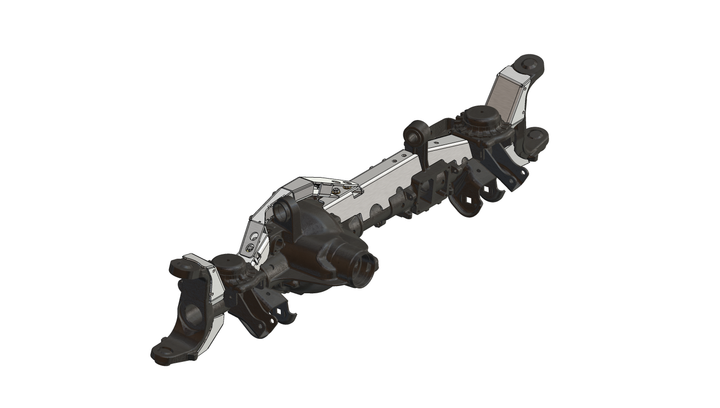

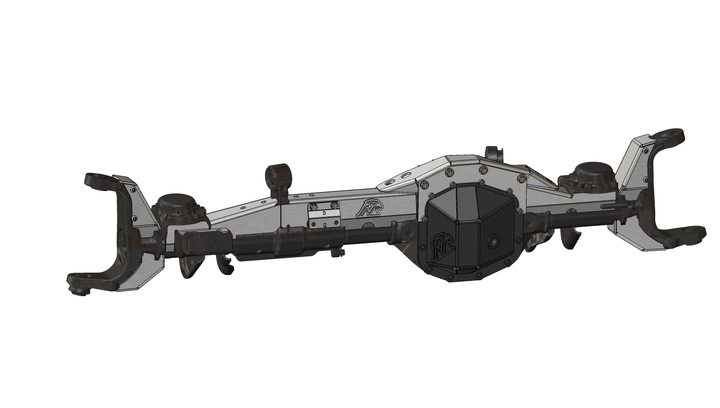

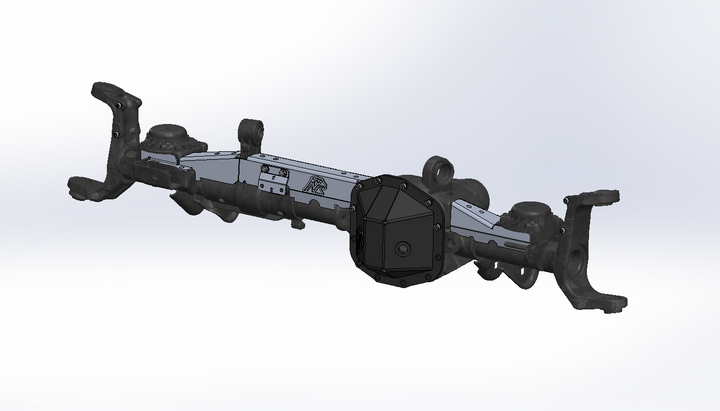

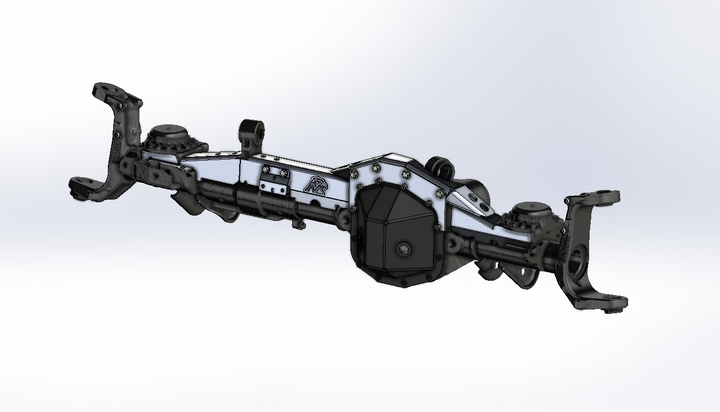

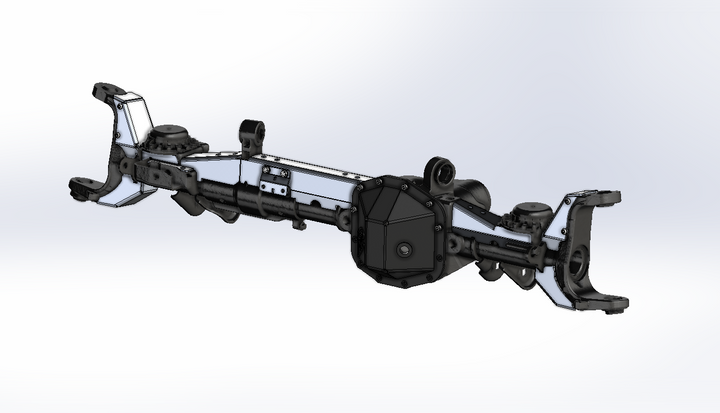

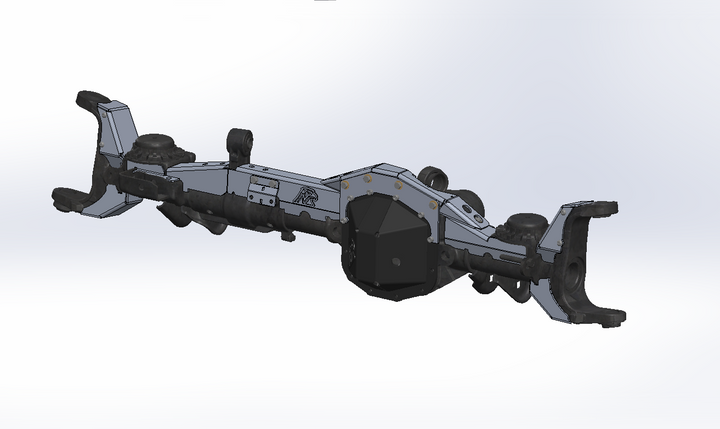

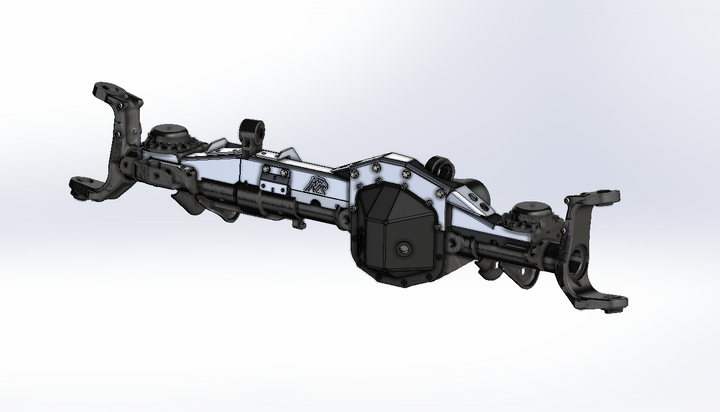

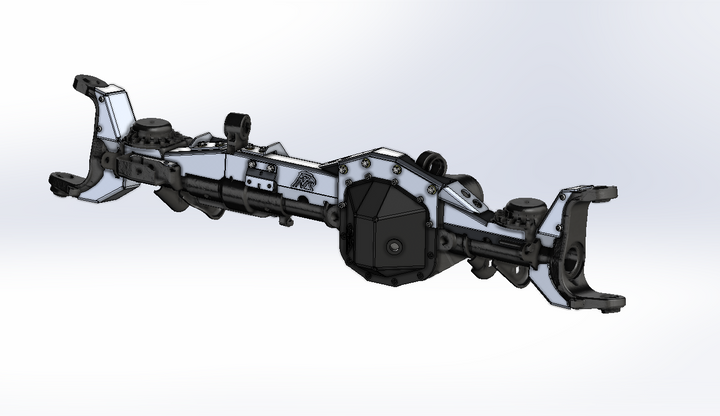

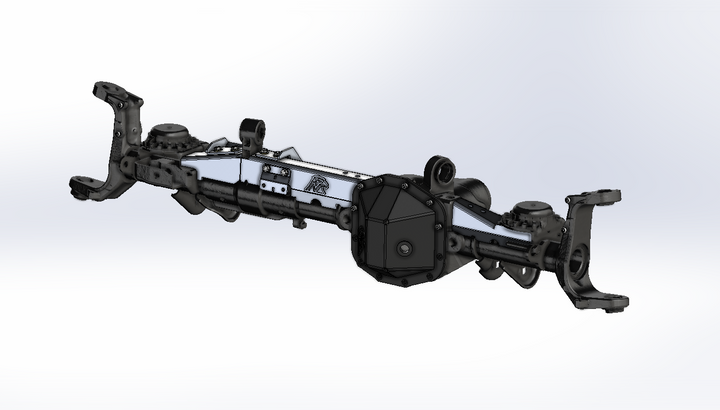

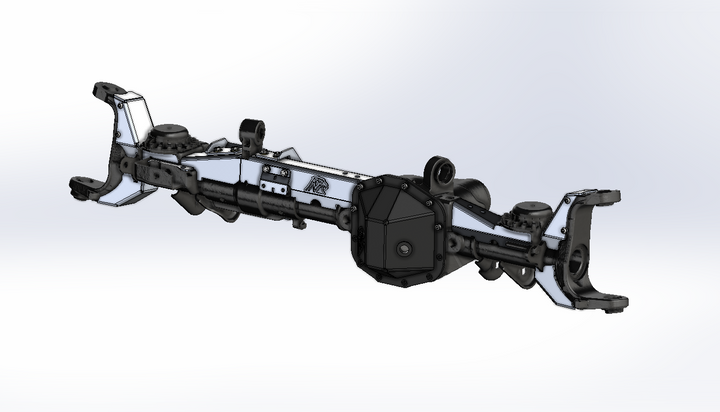

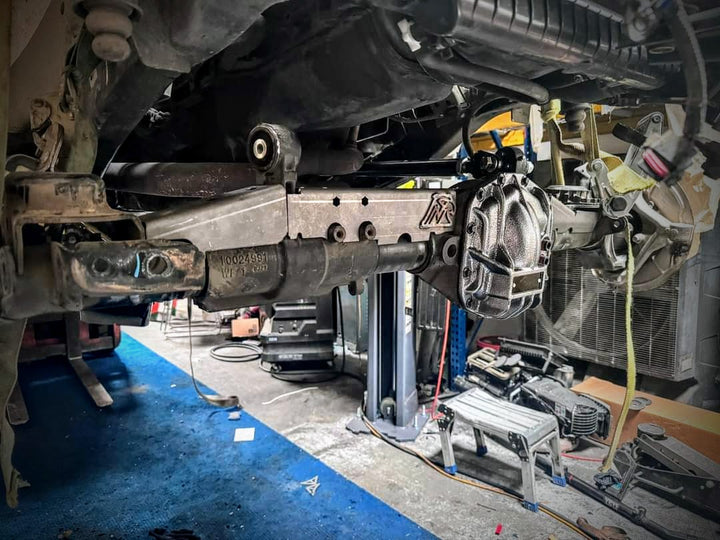

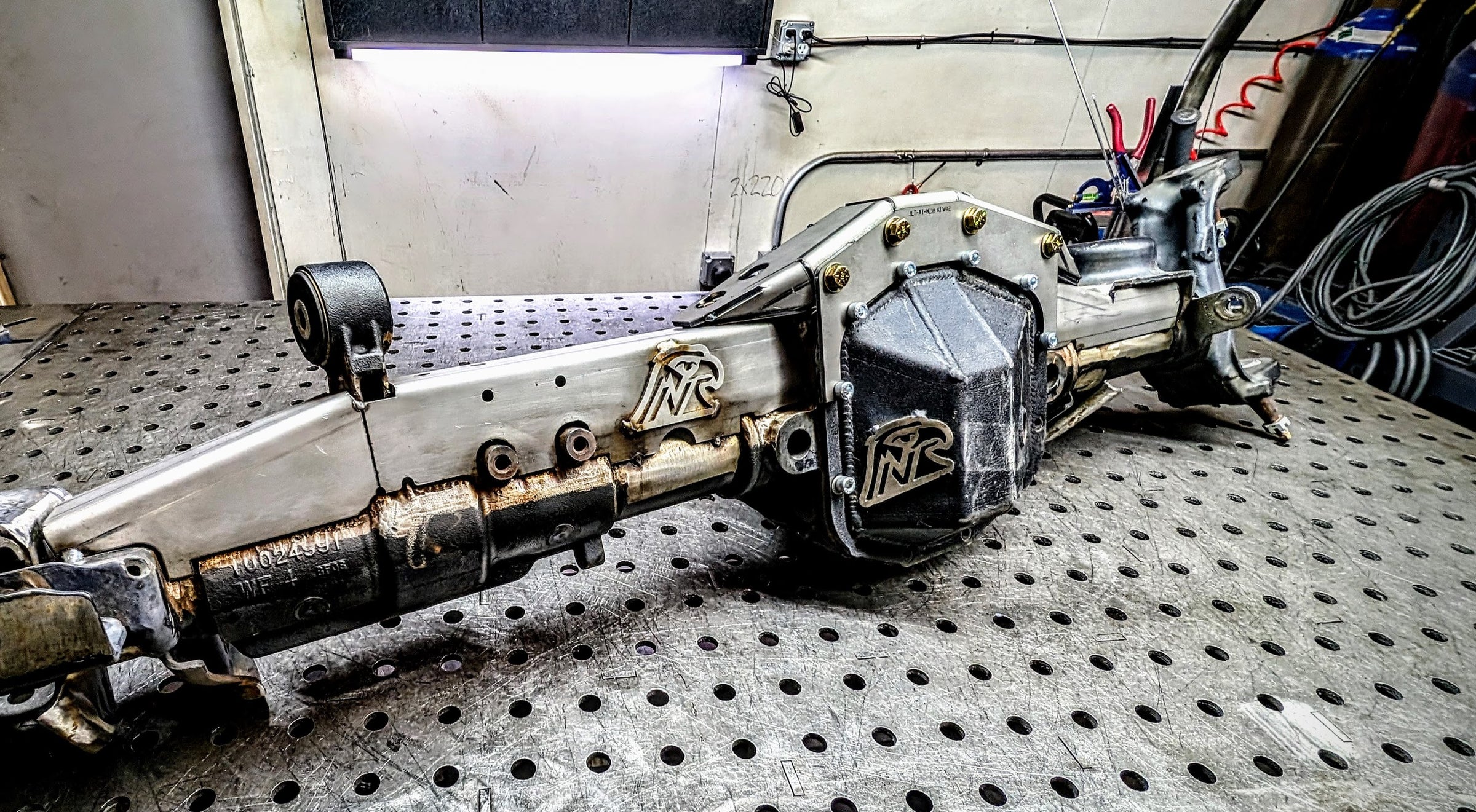

This truss reduces deflection of the axle housing, and ties in everything from one end to the other to prevent the dreaded bent or broken front axle.

what is a fad?

It allows for reduced wear/fuel consumption in 2WD by means of an engagement collar on the 2 piece passenger side axle shaft. 392/4XE Models use a FAD Delete Plate, however they still have the brittle/weak FAD casting in the axle housing.

Regardless of JL/JT model, a truss is a must to address this part of the housing!

do it yourself - faq

just how "DIY" friendly is this?

The cast center section and cast FAD section of the housing require specific pre-heating and post-cooling techniques. Improper technique can cause damage to your axle housing. Welding an axle truss properly is best done by a competent welder experienced with welding cast. If you're not experienced with this, reach out to your local off-road shop!

differential tie in

What diff covers will the differential tie in work with?

This truss system is designed to tie in with our Next Venture Heavy Duty M210 Differential Covers, however it will work with many other similar fabricated covers with 3/8" thick flanges. Curious if it will work with yours? Give us a call!

jl/jt m210 truss FAQs

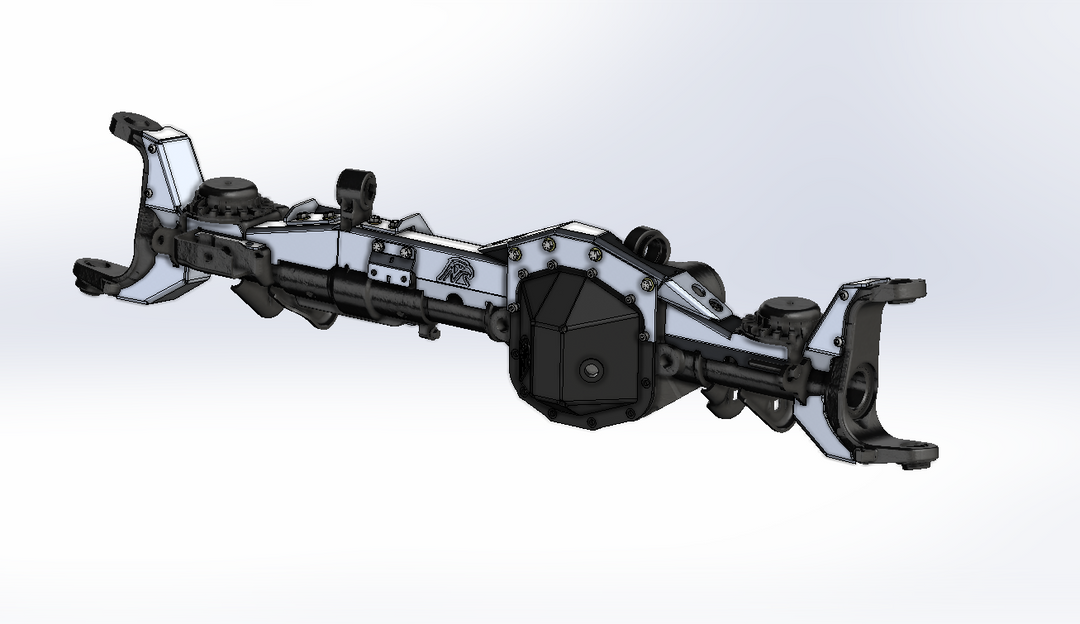

That depends on which components you intend to weld in. Lift is less important than bump stop additions however in this case.

To weld in everything, the upper bridge section of the truss will require a 2" bump stop addition. If you're opting only to weld in the lower profile sections, a 1.5" bumpstop addition is recommended.

No Lift is required for the outer "C" gussets.

We do suggest cycling your suspension and testing your bump stops each time you make a change to the configuration of your vehicle.

Yes. Any of the options that are available can be added on later to this system. Please note that the FAD Rear Tie In Bracket requires a FAD Delete to be done prior to it's installation.

No. A delete plate is included, but it will require the use of an aftermarket 1 piece axle shaft, in addition to the use of a tazer/programming from a dealer in order to properly finish the deletion.

A FAD Delete replaces the electronic module/shift actuator and fork mechanism with a delete plate.

Mopar/Factory 392 and 4xE delete plates have a shift fork that is permanently in the "engaged" position and still utilize a 2 piece passenger side shaft in most cases.

Many aftermarket delete's use a 1 piece shaft, and eliminate the need for a shift fork at all.

With enough fabrication/machining anything is possible; but the short answer is still NO.

Even with an extensive amount of fabrication, the passenger side axle shaft seal is integrated into the FAD casting to bring oil to the FAD actuator. There is no provision to install an inner axle shaft seal in the differential center section like on most Dana axles. Without this seal, your differential would not stay oiled properly.

It adds a total of 1.5" of vertical height above the differential at the ring gear; however it sits lower than the factory upper control arm mount and therefore does not increase the vertical height of the housing overall.

If you are installing the upper truss component that is bolt on, it may need to be removed in order to use proper installation tools to remove and replace the upper control arm bushing on the driver side of the housing. The passenger side upper control arm bushing and other serviceable items are unaffected.

While the upper C gussets do tie into existing holes on the outer C's, they are intended to be fully welded. The upper bolt locations are pre-threaded from the factory, and the lower bosses usually are not yet tapped and will require thread tapping before they can be used.

Minor modifications will be required in fabrication and welding if you have a Mojave/XR/XR392 model or a JL/JT vehicle that comes with one of these redesigned housings.

We have not yet verified fitment of the base truss or C gussets on the M186/Adantek Dana 30 Housings found in most Non-Rubicon or Export/International Market JLs/JTs. The differential tie in bolt pattern is *NOT* a match, so we can confirm that the upper truss components will not work at this time.

Due to the difference in axle width, and the many changes that originate at the factory, the C gussets we offer will not work on the narrow track/non-rubicon JL/JT housings in most cases.

Additional Details

*If you completed an engine swap on your JLU, a 1.5"+ lift may be required!*

Products are designed and fabricated to fit vehicles that have varying tolerances from the factory, minor hand fitting may be required.

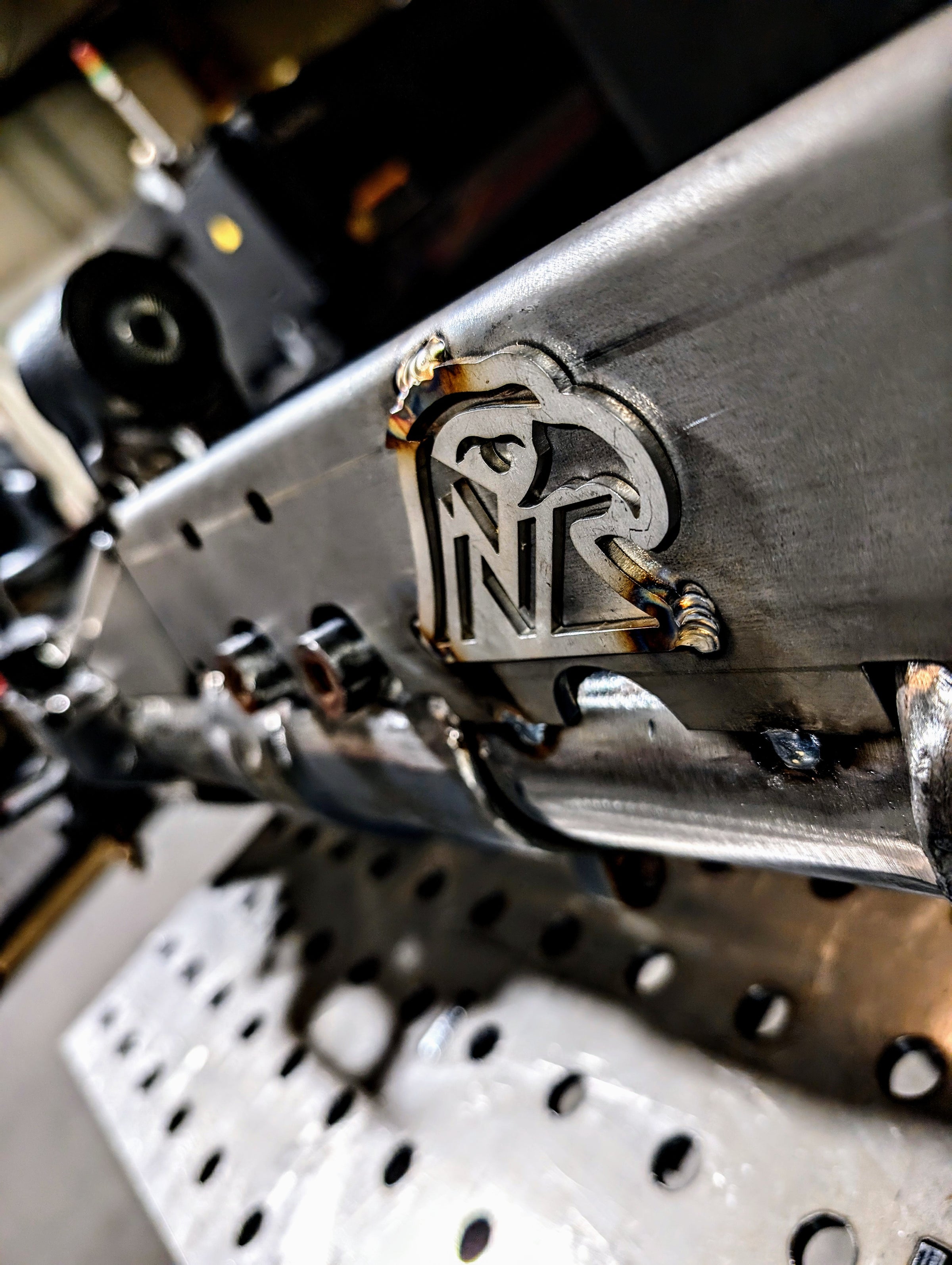

Truss products are shipped bare metal and ready to weld! Bare metal products may have scratches or surface imperfections as a result of raw material handling, manufacturing, and fabrication. Additional finishing, sanding, and prep work may be required if you wish to also have them finished with a smooth powder coat or paint.

Projected lead times are estimates only, and are subject to changes due to production realities, including material and labor availability and sudden variability in order volume. Lead times are not guaranteed, but we do guarantee that we are hard at work trying to produce the best product we can and get it into our customers’ hands as quickly as possible.

All Next Venture Motorsports products are laser cut, CNC formed, and hand-weld with pride in the USA. We are a Colorado-based business, and welcome visitors by appointment at our Grand Junction, CO headquarters. We hope to see you out there on the trail soon!

Why next venture?

parts inspired by the trail

Our team got into the game after rock crawling, wrenching, fabricating and being inspired to design and build parts for what we love to do: hit the trail.