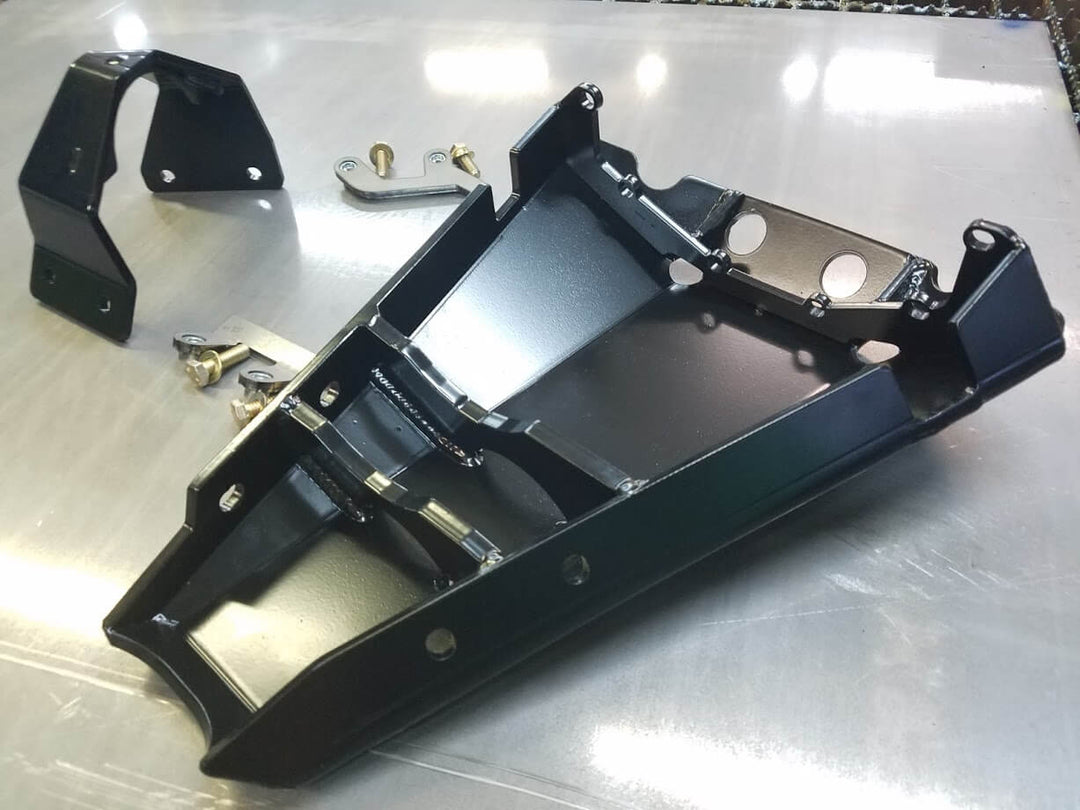

The JL/JT Rear Diff Skid (RDS) is designed to provide protection for the vulnerable ribs on JL and JT Rear Differentials, and provides a smooth surface to slide over obstacles.

Looking for a matching Front Differential Skid? Check out our JL/JT M210 Front Diff Skid here.

--

JL JT Rear Diff Skid & Pinion Guard (RDS) for M220

The JL/ JT Rear Diff Skid (RDS) is a heavy-duty diff skid designed to protect the vulnerable ribs on the JL/ JT rear differential, and provides a smooth surface for you to slide over obstacles.

The new JL Wrangler/ JT axles are a fantastic upgrade over the previous models. However, their shape is not ideal for rock crawling. The thin, exposed lip on the back of the housing is a rock grabber. It also creates a potential risk of cracking a housing or fluid loss if hit hard enough or worn through over time.

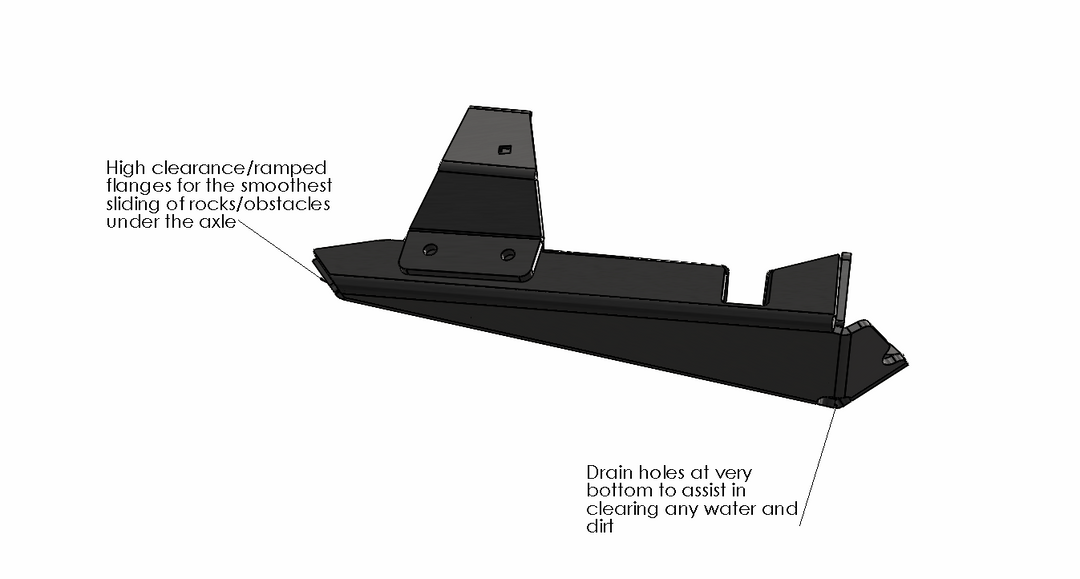

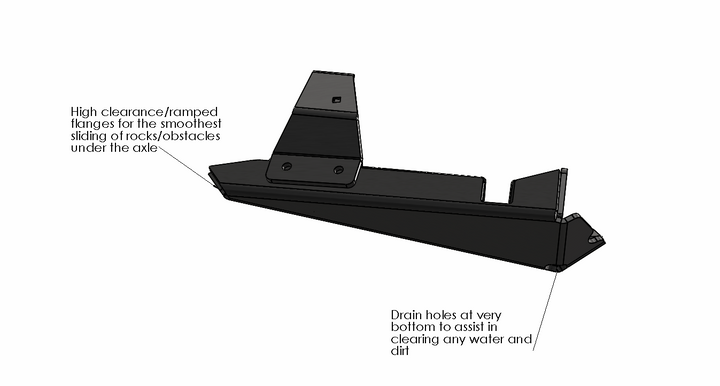

As any rock crawling enthusiast will tell you, every inch of ground clearance matters. Anything on your Jeep's underside that can be smooth should be, or it's likely to catch on an obstacle. Our JL/ JT Rear Diff Skid (RDS) is CAD designed with 3D modeling to retain every bit of possible ground clearance for critical protection you need on the trail. Additionally, you gain clearance to any adjacent skid plates.

If you find yourself watching the Lite Brite YouTube channel, and come across their 2019 King of the Hammer’s videos… this is one of the many pieces of metal you will hear banging against — scratch that, breaking — some of the rocks in Johnson Valley underneath their JL.

You can also check out this install video of the RDS by JL Life Offroad!

Product Details

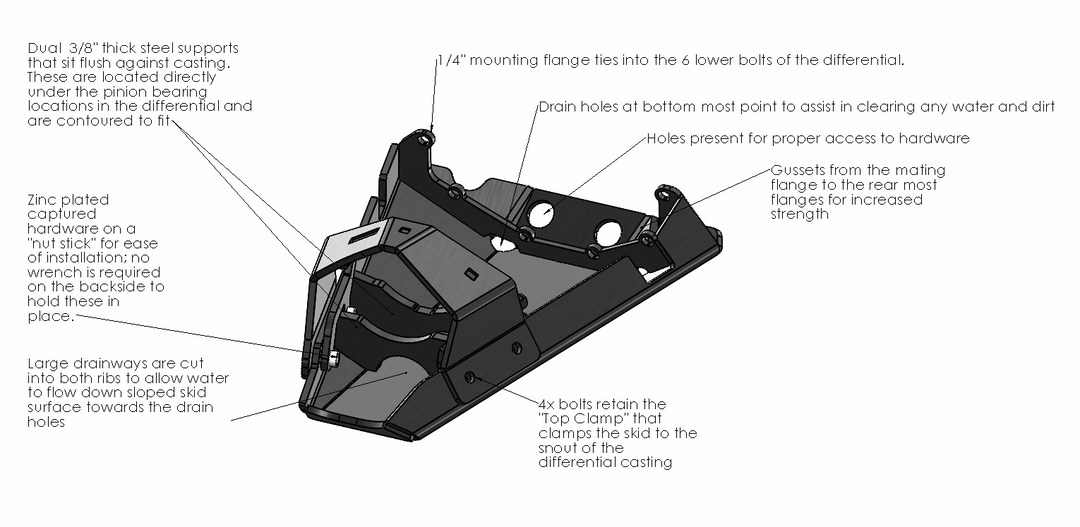

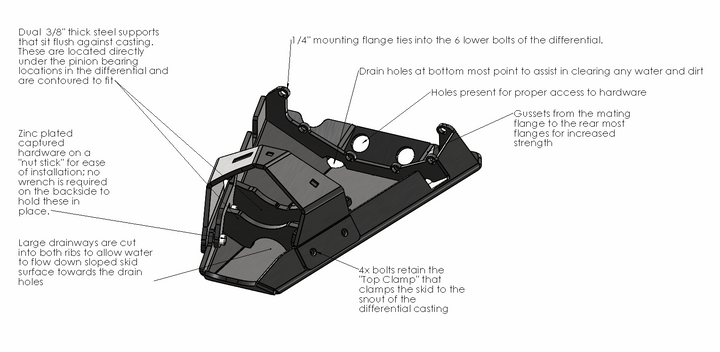

We build the JL/ JT Rear Diff Skid (RDS) from a combination of 1/4" and 3/8" thick steel. This diff skid ties into multiple locations on the differential flange, as well as clamping tight to the snout of the differential. As a result, you will distribute any force -- such as the weight of the vehicle on a rock -- over a much larger area. This skid also extends your coverage to the pinion seal and yoke/flange where the rear driveshaft attaches.

This skid fits both the JL and JT rear M220 Differentials.

*This skid is designed and recommended for use with our HD JL/ JT Rear Diff Cover * It has been successfully test-fit with TMR, CavFab, Ballistic, Under Cover Fab, and Motobilt Diff Covers by customers. It will *not* work with the Spicer aftermarket covers due to the shape/fin features. Incompatibility has also been found with G2, MetalCloak, Ox Locker, ARB, and Artec/Yukon covers.

Installation with a factory cover is possible, but will require a shim/spacer to account for the factory cover's thinner material. While a stack of washers may do the job, we also offer this laser cut spacer for a clean, 1 piece solution. For ultimate strength, protection, and rigidly tying into all 12 mounting points that the axle offers, we recommend using this product in conjunction with our HD JL/ JT Rear Differential Cover.

Included with purchase:

(1) Rear Differential Skid Plate with Top Clamp

(2) Hardware Sticks with hardware/ bolts

(12) 12 Point Flange Bolts Class 10.9 Chromed (enough for matching hardware all the way around the rear diff cover)

FAQs

-

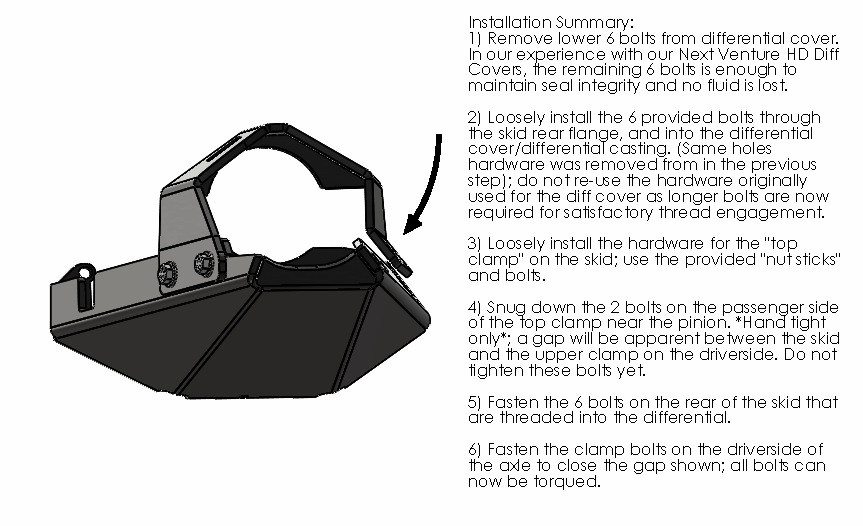

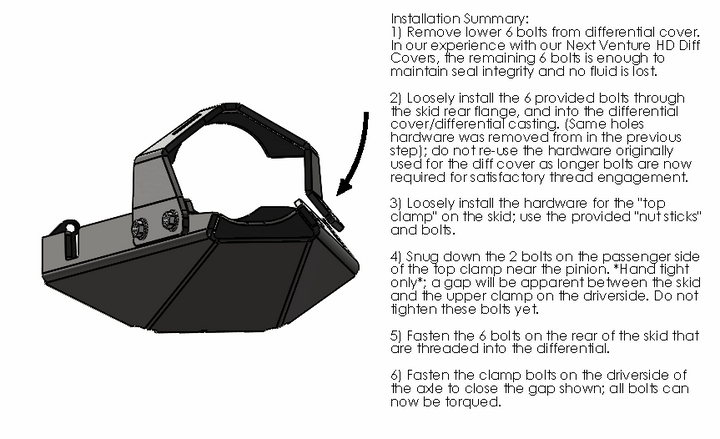

Do I need to empty my differential fluid before installation?

In our experience, no. The factory gasket in addition to the very thick/ rigid flange on our HD Diff Covers has not leaked any fluid when removing the lower 6 bolts on the cover, as long as the upper 6 bolts are left in place during installation.

-

This ties into the diff cover; will it cause the gasket to begin leaking fluid if hit hard enough?

In our experience, that would be unusual. When properly torqued with a good gasket, the clamping force of the differential cover bolts along with a very thick/ rigid flange. This prevents most impacts from compromising the integrity of a good gasket/ seal between the cover and differential. Our diff skid extends so far forward, it arguably offers more leverage than the diff cover itself. This is why the pinion/ snout clamp components and hardware are so substantial.

- What are the torque specs for installation? 26 ft/lbs on the M8 Hardware, and 37 ft/lbs on the 3/8"-16 Hardware

Additional Details

Products are designed and fabricated to fit vehicles that have varying tolerances from the factory, minor hand fitting may be required.

Products are shipped bare metal unless otherwise specified by the customer. Bare metal products may have scratches or surface imperfections as a result of raw material handling, manufacturing, and fabrication. However, these imperfections are easily covered up with a textured powder coat finish. Additional finishing, sanding, and prep work may be required if you wish to also have them finished with a smooth powder coat or paint.

Projected lead times are estimates only, and are subject to changes due to production realities, including material and labor availability and sudden variability in order volume. Lead times are not guaranteed, but we do guarantee that we are hard at work trying to get the best product we can produce and into our customers’ hands as quickly as possible.

All Next Venture Motorsports products are laser cut, CNC formed, and hand-weld with pride in the USA. We are a Colorado-based business, and welcome visitors by appointment at our Grand Junction, CO headquarters. We hope to see you out there on the trail soon!

Why next venture?

parts inspired by the trail

Our team got into the game after rock crawling, wrenching, fabricating and being inspired to design and build parts for what we love to do: hit the trail.