PRODUCT DETAILS

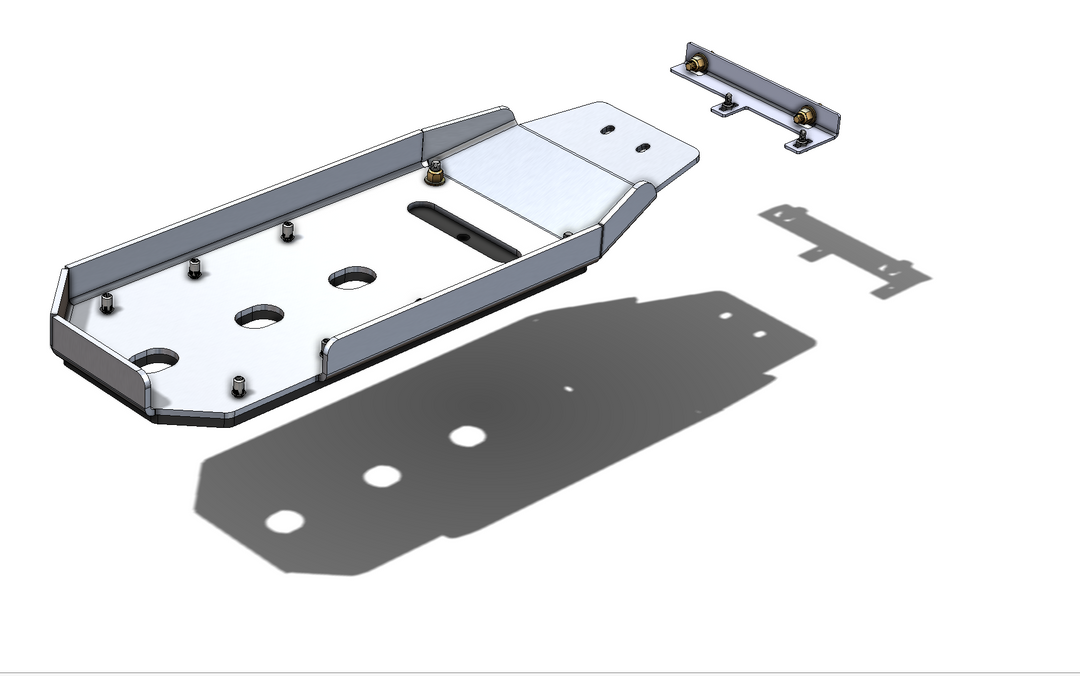

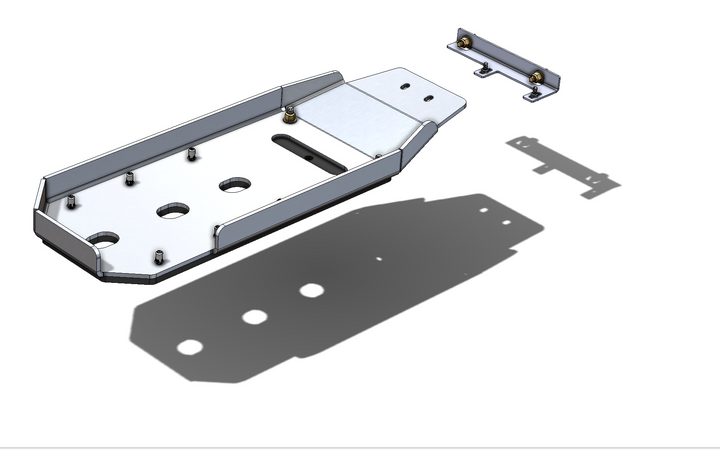

Need to add on an e-torque skid for your 2.0 or 3.6 JLU? This skid is designed for use with our full belly skid system, however it can be used stand alone to offer additional protection to your e-torque equipped JL.

Installation is accomplished via rivet nuts to existing holes in the factory skid plate -- so no removal of the factory skid or e-torque system is required. A rivet nut tool is highly recommended to make this installation a quick one.

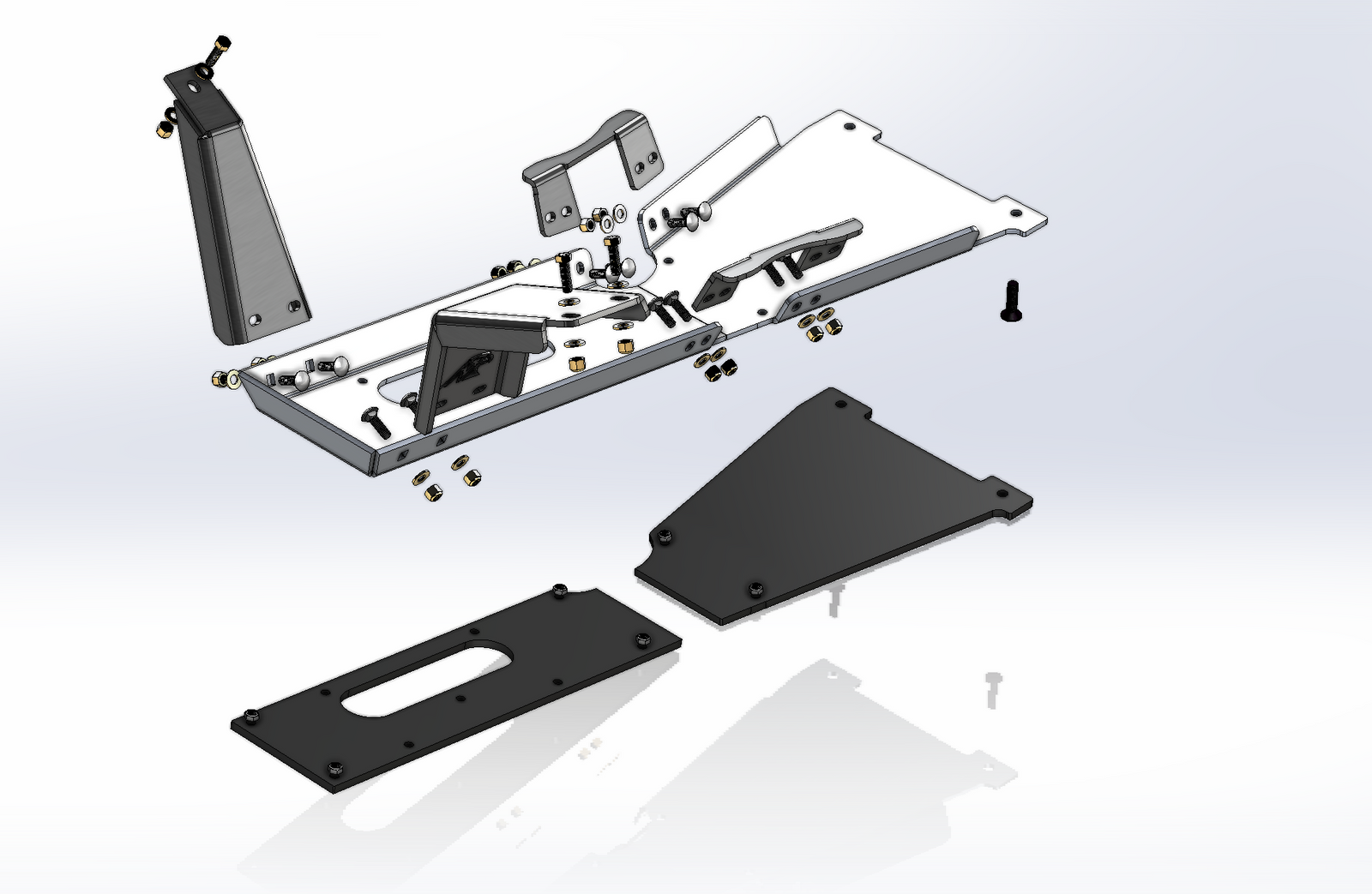

We build these skids out of 1/4" thick 5052 Aluminum because of its superior formability and strength -- compared to many other alloys. The design and shape of the skids largely determine how rigid they will stay over time. We've designed these belly skids to tuck bolt heads up and out of the way, where possible, and all holes on the bottom surface are countersunk into the UHMW skid surface when optioned with UHMW.

UHMW - The Ultra High Molecular Weight Option

Want to make these skid plates slippery and even more impact-resistant? Select the UHMW Option! UHMW stands for Ultra High Molecular Weight Polyethelene.

It's the 3/8" thick black cutting board like material that can be optioned onto these skids; it is more abrasion resistance than carbon steel, and it's fairly light weight. It helps to better distribute and absorb impacts, and keep you sliding along rather than getting stuck or hanging up on an obstacle since it's slippery and self lubricating. If you select this option, the UHMW will come included in your skid systems packaging ready to bolt on to each skid.

uhmw faq

will the uhmw hardware damage the fuel tank?

No: The UHMW panels are secured to the 1/4" aluminum skid using small nylock jamnuts. Countersunk bolts of very specific lengths are used to avoid excessive threads on the backside (top) of the skid. We also provide rubber snap on covers to provide additional protection to prevent wear on the fuel tanks!

jl/jt belly skid FAQs

A 1.5" lift (or just 1.5" bump stop extensions on the front) is recommended for clearance to the motor mounting brackets on 3.6 V6 JL models from 2018-2020. JT 3.6 V6 and JL 3.6 V6 model year 2021 and newer can typically be run without any lift or bumpstop extensions.

No lift or bump stop extension is required for the 2.0 I4 engine, 4xE, Diesel or 392, however we do suggest cycling your suspension and testing your bump stops each time you make a change to the configuration of your vehicle.

These belly skids will work with Rock Krawler*, EVO, and Teraflex** Long Arm kits with minor modifications.

*Please note that the Rock Krawler "Rockzilla" kit is an entirely different animal from the conventional long arm kits and requires deletion of the factory fuel tank and replaces it with a custom fuel cell. Our skid system is not compatible with this, however we are working on skids that will work for this!

**Teraflex long arm kits do require slight modification to the fuel tank skid as this suspension kit relocates the rear lower control arms underneath the frame rail where the fuel tank skid would otherwise interfere -- 5 minutes with a cutoff wheel prior to installation resolves this issue.

Yes; however you will have to remove your belly skids if they are already installed in order to place the UHMW onto your bare metal system. We carry special washers to fill the previously countersunk aluminum areas of the skid that are required before installing the UHMW. Contact us for more details!

Additional Details

The skids shown in some images are pre-production units; production units shipping now have countersunk bolts that mount flush on the bottom-most surface of the skids.

*If you completed an engine swap on your JLU, please contact us before ordering so we can get everything right! 2 Door Skids Are Now Available As Well!

Products are designed and fabricated to fit vehicles that have varying tolerances from the factory, minor hand fitting may be required.

Products are shipped bare metal unless otherwise specified by the customer. Bare metal products may have scratches or surface imperfections as a result of raw material handling, manufacturing, and fabrication. However, these imperfections are easily covered up with a textured powder coat finish. Additional finishing, sanding, and prep work may be required if you wish to also have them finished with a smooth powder coat or paint.

Projected lead times are estimates only, and are subject to changes due to production realities, including material and labor availability and sudden variability in order volume. Lead times are not guaranteed, but we do guarantee that we are hard at work trying to produce the best product we can and get it into our customers’ hands as quickly as possible.

All Next Venture Motorsports products are laser cut, CNC formed, and hand-weld with pride in the USA. We are a Colorado-based business, and welcome visitors by appointment at our Grand Junction, CO headquarters. We hope to see you out there on the trail soon!

Why next venture?

parts inspired by the trail

Our team got into the game after rock crawling, wrenching, fabricating and being inspired to design and build parts for what we love to do: hit the trail.