introducing the 7000-series

The Ultimate Jeep Skid Plate System: 7075 Aluminum, Enhanced by UHMW Skid Surfaces

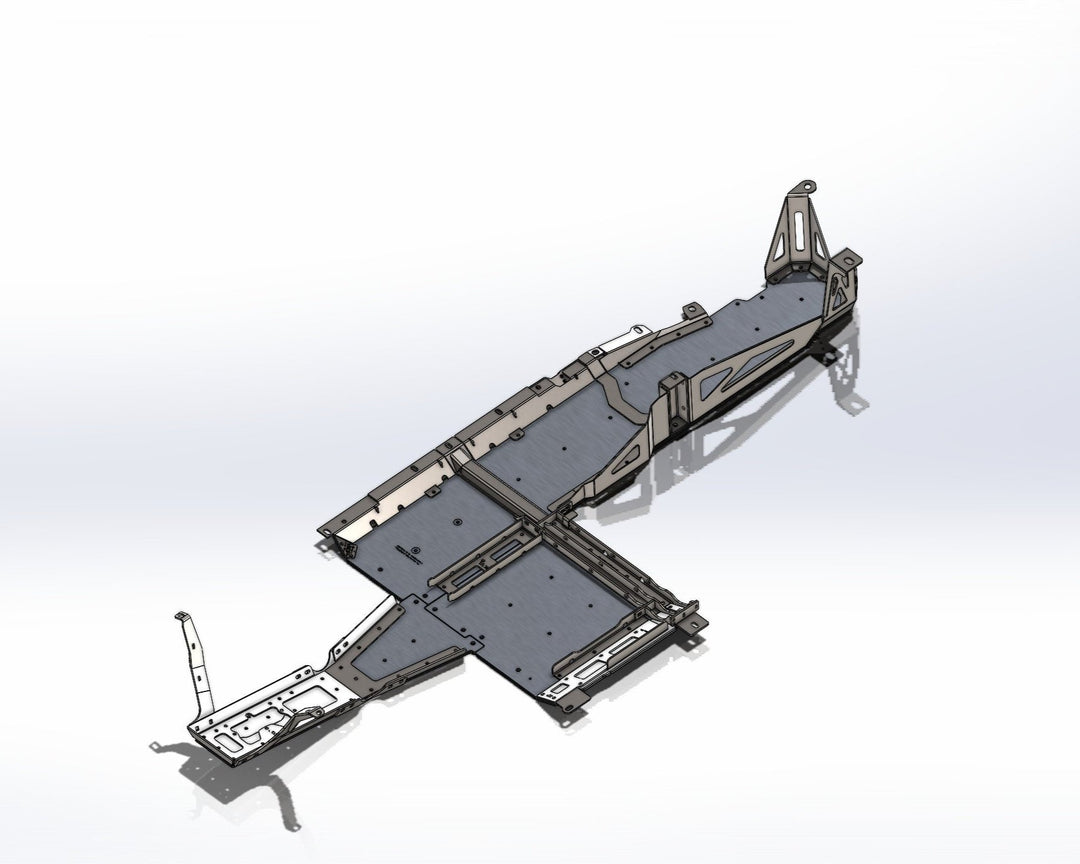

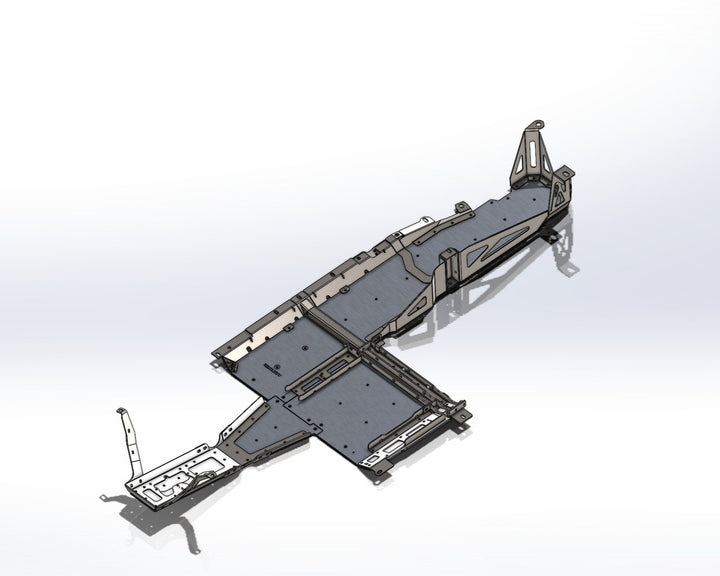

Off-roading can be rough on your Jeep, but with the 7000-Series Skid Plate System, you’ll be prepared for anything the trail throws your way. Not only is this built for serious off-roaders, it's been designed and engineered by real rock crawling enthusiasts. This modular skid plate system combines 3/16" 7075 aluminum, zinc-plated steel reinforcements, and a 1/4" UHMW wear surface to provide unparalleled protection and performance for your Jeep. With skids for the Engine & Transmission, Transfer Case, and a two-piece Fuel Tank Skid, your drive train and undercarriage is shielded from the toughest terrain, minimizing added weight while maximizing seamless, smooth protection.

lessons from building JL/JT skids the past 5 years, and other platforms for over a decade.

This design comes from decades of wheeling. The muddy hill climbs of Tennessee, and deserts of Arizona, Utah and California, have brought us here. Not only is this inspired by our product development teams time on the trail, and the Ultra4 Racing Jeeps that rely on our parts, but also from feedback and experiences we get from you,our customers.

King of The Hammers 2024: The #4655 Rock Krawler/Jeep Racing JL with a freshly installed Next Venture Engine/Trans Skid that would evolve into the 7000-Series Skids.

Whether you’re planning your first trip to the Rubicon, or your 10th trip to The Hammers, this one is built for you.

The 7000-Series Advantage: A Seamless, Rock-Slip Design

No Gaps, No Hang-Ups. One of the most overlooked aspects in off-road skid systems is the presence of gaps between skids, which can create vulnerable points where rocks and debris can catch. Our skids are meticulously designed to form a completely smooth, gap-free surface, preventing any point of contact that could get you stuck. This ensures your Jeep slides effortlessly over obstacles without the risk of hang-ups—letting you conquer the trail without hesitation. Looking for the oil drain hole? It's a removable, gapless, flush mounted access panel!

Steel | 6061-T6 | 7075-T6

the material throw down

Done watching "test videos" where a MFG calls the product "bulletproof" because a small caliber bounces off their skid?

We got creative and had some fun with a more analogous test. Spoiler alert: 7075-T6 really stands out.

Why Our Skid Plate System Stands Above the Rest

Our 7075-T6 is processed flat, and remains unwelded to retain its original strength. 7075 combined with the structural benefits of the zinc-plated steel bracketry, heavy duty crossmembers, and UHMW skid surfaces, give your Jeep a skid plate system that’s tougher, longer-lasting, and designed for serious rock crawlers who push their vehicles to the limit.

modular design for maximum coverage

Engine & Transmission Skid

We have watched a few folks discover this first hand: any damage to the oil pans of your engine or transmission can leave you stranded on the trail, waiting for help. This combined engine and transmission skid features a gap-free design including an access panel for oil changes and maintenance to prevent hang-ups, with steel reinforcements along all edges, and a 1/4" UHMW surface to ensure durability and frictionless performance to get you home at the end of the day.

oil changes

Access panel

Need to do a quick oil change? Drop a few bolts to remove the aluminum and UHMW access panel instead of removing the skid.

Transfer Case Skid

Built to absorb impacts, the Transfer Case skid offers superior strength with no gaps where it meets the engine & transmission skid in addition to the fuel tank skid, so rocks won’t find a place to lodge themselves. While the transfer case itself has no oil pan, its cast aluminum casing is something we have seen fail if left exposed to rocks, and even fail when steel skids beneath have collapsed and rubbed through the casing over time. A working transfer case is required for 4 low, 4 high, and even proper 2wd power transmission to your axles.

2 Piece Design

Fuel Tank Skid

You won’t get very far without fuel, and it’s never a fun mess to clean up if you do manage to spring a leak in your fuel tank. Our two-piece Fuel Tank skid provides smooth, continuous protection for your fuel system, making installation easier without compromising on full, gap-free coverage. This skid meshes seamlessly with the transfer case and engine & transmission skids, and features the same steel reinforcements you’ll find across the rest of the skid system.

heavy duty steel

cross members

Backing up the belly of the beast, is a heavy duty steel crossmember. This connects your front fuel tank skid, rear feel tank skid, transfer case, and if you opt to add it in - your mid-exhaust skid plate. It even has a brace to the factory transmission crossmember in front of it.

We weren't messing around: this is 1/4" thick steel, as it's integral to nearly everything else in this system.

frame

mounting rails

Along the outside edge of the fuel tank, you'll find 3/16" thick steel mounting rails. These provide a strong cross section underneath your frame rails, and feature internal gussets for additional strength.

These ultimately are covered up by UHMW, and feature a 40 degree "boatside" slope on them to keep you moving along on the trail.

Key Benefits

- Seamless, Smooth Protection: The gap-free design prevents rocks or debris from catching on the skids, giving you uninterrupted, frictionless movement over rough terrain.

- Total Protection with Minimal Weight: The 7075 aluminum provides a high-strength, lightweight shield, preserving your Jeep’s agility on rocky trails and steep climbs.

- Zinc-Plated Steel Reinforcements: In critical impact areas, zinc-plated steel brackets provide extra strength, while ensuring corrosion resistance.

- Frictionless Performance with UHMW: The 1/4" UHMW wear surface helps distribute impacts and allows your Jeep to glide over obstacles, further reducing the risk of getting stuck.

- Reduced Wear On Drivetrain and Axles: By reducing friction and hang-ups, you also reduce the number of full-throttle attempts you might have needed with your previous skids to make the ‘breakover’ on obstacles. This means less wear and tear on your u-joints, CVs, axle shafts and drivetrain over time. Next time your spotter says “bump it”, this helps really make it count!

- Easily Make It Like-New: Ever need to clean up the bottom of your Jeep after years of tough trails? Just replace the UHMW and your skids will look like new!

why choose next venture?

At Next Venture Motorsports, we understand the demands of true off-road enthusiasts. From our early days of conception in the rocks of Southern Arizona, to product testing across the country and even Ultra 4 test vehicles, our product development team lives and breathes motorsports on the rocks.

Our 7000-Series Skid Plate System combines the latest materials and technologies—7075 aluminum, zinc-plated steel bracketry, and UHMW skid surfaces—to create a product that’s as durable as it is lightweight. Engineered to provide maximum protection in the most critical areas, this system is built to keep your Jeep’s undercarriage and drivetrain safe while you conquer any terrain.

Ready to Upgrade?

With our 7000-Series Skid Plate System, you’re not just getting a piece of armor; you’re investing in reliable, American Made, long-lasting protection for your vehicle. The combination of lightweight materials and corrosion resistance ensures your Jeep performs better and lasts longer, even in the harshest conditions.

Order Now and Get Ready For Your Next Adventure!

The 7000-Series Skid Plate System is available now! Equip your Jeep with the ultimate in strength, corrosion resistance, and off-road performance. Place your order today and hit the trails with confidence!

done in house

made in usa

We make these in house. That means Developed, laser cut, cnc formed, welded, packaged & shipped from our facility in grand junction, colorado.

jt 7000-Series belly skid FAQs

- There's some assembly required, as these are "flat pack" items on delivery. Plan 60-90 minutes to assemble the pieces before you begin installation.

- Make sure you have basic hand tools including allen keys/sockets!

- Drive until your fuel tank is nearly empty! Removal of the factory fuel tank skid is required for installation.

- Watch The Install Video!

These skids essentially ship as "flat packed" items, and require about 60-90 minutes of assembly before they're ready to bolt up. Installation is typically quoted as 5-7 hours of labor on a lift. If you're doing this in your garage, we would give yourself the weekend, and a 2nd set of hands may be helpful.

Basic hand tools are a must. Sockets, wrenches and allen keys will do it, however allen sockets will speed up the process. A pair of ratchet straps is useful in order to properly drop the factory fuel tank skid without removing the fuel tank from the vehicle.

Nearly every bolt is countersunk/recessed, and the threaded inserts are twist-resistant "hex" rivet nuts into hex cutouts.

A 1.5" lift (or just 1.5" bump stop extensions on the front) is recommended for clearance to the motor mounting brackets on 3.6 V6 JL models from 2018-2020. JT 3.6 V6 and JL 3.6 V6 model year 2021 and newer can typically be run without any lift or bumpstop extensions.

However we do suggest cycling your suspension and testing your bump stops each time you make a change to the configuration of your vehicle.

These belly skids will work with Rock Krawler Suspension Long Arm Kits out of the box* We run their Service Free Adventure Series on our Shop JL.

EVO, and Teraflex** Long Arm kits also work with minor modifications.

* These skids will 100% bolt on with RK kits with the use of our HD Transmission crossmember. Minor modification will be required if you wish to use the factory crossmember. Please note that the Rock Krawler "Rockzilla" kit is an entirely different animal from the conventional long arm kits. Call us if you have one of these!

**Teraflex long arm kits do require slight modification to the fuel tank skid as this suspension kit relocates the rear lower control arms underneath the frame rail where the fuel tank skid would otherwise interfere -- 5 minutes with a cutoff wheel prior to installation resolves this issue.

Yes. This is not optional. Many systems might keep the factory fuel tank skid, but we are after weight savings and increased belly clearance. The fuel tank stays in the vehicle during this process. Just remember to prep for installation by driving until you see the "E" light come on!

If you purchased a MOD Skid Kit prior to November 2024 for your JL or JT, than most of these components will mesh. You can run our original Engine skid with the new 7-series Fuel Tank/Transfer case or vice versa. You must run the same generation fuel tank and transfer case skids however due to crossmember differences. When mixing and matching parts, keep in mind that the 7-series sits slightly higher - by about 3/16 of an inch.

Every time you modify your vehicle, you are going to effect it's weight and performance. In the nearly 5 years we have been producing skids for the JL platform we have not seen skids cause an overheating issue. There's a reason aluminum is commonly used to make heat sinks - as it's a good thermal conductor and will actually help to dissipate heat in addition to keeping things lighter vs full steel skids.

Sliders that are body mounted (like factory) work. If you're looking for frame mounted sliders that are compatible, check out our Rimrocker Series!

UHMW stands for Ultra High Molecular Weight Polyethelene. It's the 1/4" thick black cutting board like material that is included on these skids; it is more abrasion resistance than carbon steel, and it's light weight. It helps to better distribute and absorb impacts, and keep you sliding along rather than getting stuck or hanging up on an obstacle since it's slippery and self lubricating.

The weight of the UHMW on the 3.6 V6 JLU is under 24 lbs total! It's pretty light weight!

In the 4 years we have offered replacement UHMW kits, we have had under 5 pieces of replacement UHMW for belly skids requested. This stuff lasts a long time!

In terms of strength, 3/16" thick 7075-T6 aluminum is stronger than 1/4" thick 6061-T6 aluminum. Here's a breakdown:

Yield Strength:

- 7075-T6: Around 73,000 psi

- 6061-T6: Around 40,000 psi

This means 7075-T6 has nearly twice the yield strength of 6061-T6, which is crucial for resisting permanent deformation under load.

Ultimate Tensile Strength: - 7075-T6: Around 83,000 psi

- 6061-T6: Around 45,000 psi

Again, 7075-T6 is significantly higher in ultimate tensile strength, indicating it can handle higher loads before failure.

Thickness Difference:

While 1/4" thick 6061-T6 is 33% thicker than 3/16" thick 7075-T6, the strength difference between the two alloys more than compensates for the slight thickness increase of 6061-T6.

In summary, even at a thinner thickness, 3/16" 7075-T6 aluminum outperforms 1/4" 6061-T6 in terms of both yield and tensile strength, making it better suited for applications requiring high strength and durability.

uhmw faq

will the uhmw hardware damage the fuel tank?

No: The UHMW panels are secured to the aluminum skid using small nylock jamnuts. Countersunk bolts of very specific lengths are used to avoid excessive threads on the backside (top) of the skid. We also provide rubber snap on covers to provide additional protection to prevent wear on the fuel tanks!